marklin-users.net community | Forum

»

General topics

»

H0-scale

»

250mm radius curves - flex track or fixed track pieces

Joined: 15/10/2006(UTC) Posts: 2,319 Location: Washington, Pacific Northwest

|

One of the features I'd like to put on some part of my layout is a street tram (Straßenbahn) running a circuit through a part of a city. Step 1: (for my era) was find the right tram: that seems solved with the 2017 new Roco model 52580 (2 conductor DC) which will run on its own loop so the DCC control over the rails is no issue.  Now its 1 segment longer sister (the 52581) has the same wheel layouts effectively and Roco indicates it can make 250mm radius curves, so I am guessing its a safe bet to think the shorter 52580 can also make a 250mm radius curve. Trams, making turns in motor vehicle intersections, need tight turns, no surprise. So that brings me to my current question of... Step 2: how to make a layout with that tight of an H0 bend. The options appear to be

- flex track - and if so, is there a guide/tool/technique to bending that tight of a radius?

- premade track - like Tillig 87790 and then piecing it all together (if plastering asphalt) or Tillig 87756 if deploying the cobblestone effect. ( Tillig: https://www.tillig.com/Strassenbahngleis.html or Luna: http://www.luna-tram.ch - I did read some German advice on forums (Drehscheibe) that warn folks away from the Tilig/Luna hollow steel track as the protective coating wears through and then the track begins to rust, and the plastic pavement isn't very nice optically)

My first instinct is to look at the flex track solution, because I could then make sure no rail joins happen in the tight bends. But then what make of flex track as the searches for flex track bending seem focused on large radius curves like 18" ( 460mm), and general useless advice of the form "if you need bends that tight move to N scale". Has anyone put down tram line using flex track or pre-made pieces with these very tight bends? If so, what worked and what didn't (both techniques and/or products used) |

|

|

|

|

|

|

Joined: 23/07/2014(UTC) Posts: 8,496 Location: ENGLAND, Didcot

|

Originally Posted by: Minok  Step 2: how to make a layout with that tight of an H0 bend. The options appear to be My first instinct is to look at the flex track solution, because I could then make sure no rail joins happen in the tight bends. But then what make of flex track as the searches for flex track bending seem focused on large radius curves like 18" ( 460mm), and general useless advice of the form "if you need bends that tight move to N scale". Has anyone put down tram line using flex track or pre-made pieces with these very tight bends? If so, what worked and what didn't (both techniques and/or products used) Tryin g to curve flex track to that tight radius will give you problems unless it is very well pinned down and you have a length of the flex track as straight track each side of the bend. If you don't it is difficult to get the join at the end of the curve to be properly tangential to the straight track. In practice in the real world the track pieces were quite short so they could be transported through the city and to be able to replace a work or damaged bit without pulling up miles of tarmac or cobbles. So using set track is the prototypical way to go, although it may be worth putting power drop wires on each piece if your paving techniques are likely to foul up the rail joints and produce intermittent contact. You mention Tillig and Luna as supplying track, I have a feeling that Bemo also supply suitable track.

|

3 users liked this useful post by kiwiAlan

|

|

|

|

Joined: 15/09/2014(UTC) Posts: 684 Location: London

|

I think that when you try to bend flex track tightly, it will probably help if you make some extra cuts in the plastic webs connecting the sleepers. The problem with doing this is that the track piece, whilst gaining some extra flexibility, loses a bit of cohesion. Thus there is a further danger of the track itself distorting - this is a problem anyhow when trying to curve flex track tightly. Another problem that you may encounter is then joining the curve to a straight; it may be difficult because the curved track is under such pressure it doesn't want to play ball when lining up and getting fishplates to link. Note: all my experience is with Peco Streamline flexible track - other brands may behave diffrently.

In conclusion, when making tight curves, I would stick to set track pieces.

Carim

|

2 users liked this useful post by Carim

|

|

|

|

Joined: 15/09/2014(UTC) Posts: 684 Location: London

|

Oh yes, another thing about curves in flex track is try to offset the joints in the rails - so the two rails do not end at the same point (as they do with set track pieces), this will give a smoother curve. Of course this means that the connection to straigt track will also be offset. Best off all try to make the straight and the curve out of the same piece of flex track as joints are easier and flow better on straight track. I wish I appreciated that before I built my layout!

Carim

|

2 users liked this useful post by Carim

|

|

|

|

Joined: 15/10/2006(UTC) Posts: 2,319 Location: Washington, Pacific Northwest

|

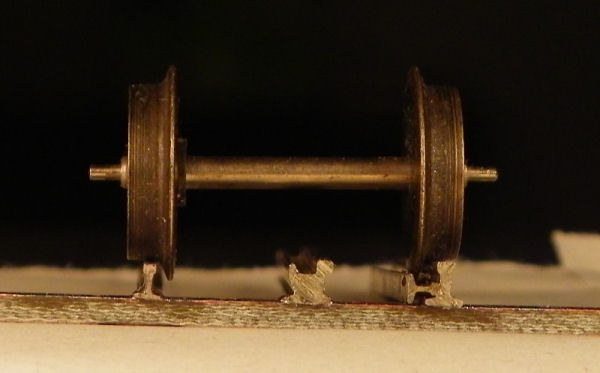

Yeah, using flextrack (from any make) may not be the ideal option. The Tillig/Luna solution has the downside of being expensive, m-track like hollow and of materials that will eventually expose the core and thus rust (I've gathered from other posts) - yet they appear to be the only solution out there in that tight configuration. [ Update 1/30/17 - I've gotten two responses on Stummiforum that indicate no issues long term (10 years) with using the Tillig/Luna tracks on layouts other than normal dirt/contamination and the issue that brings to short trams with few pickups] What I've read on the German tram forums is that folks build their trackbed by hand. There is a pre-made tram track for the right look (Orr/Swedtrack/customtraxx) but as its not NEM profile compatible, the trams with NEM wheels won't ride properly in them, and this solution is a PITA to bend well, even with the bending tools one can acquire. Here the profiles of 3 rails: Code 83 / Swedtrack/customtraxx / Combo of Code 100/75 sideways:  But similarly to that folks seem to use normal track rail (cut up flextrack I suppose, to get long bits), and then add an brass L shape to the side to get that captured groove look. It is (like customtrax) then soldered to PCB substrate sleepers carefully using gauge spacers and testing along the way. Then one can fill it with poly-enhanced plaster (and if desired ) stamp cobble patterns in it with a variety of tools/techniques (including a cool roller drum that is 3d printed). So tram lines are a whole new level of complexity it seems as the geometry restrictions combined with the way one custom builds, even small layouts (or maybe especially small layouts) require you think of the WHOLE completed layout at the start -that is not just the track, but the streets, sidewalks and buildings and their footprints. Because where you hand-build and lay your track (which must come first), determines the roads to some extent at least, and that determines the sidewalks and building footprints. The tram (Straßenbahn) area is still rather niche it seems. While there are several smaller outfits that produce cars, and some larger ones that do, many still require separate installation of motors, and I think all come without decoders. So there is really no provider of track other than one commercial solution (Tillig) and the rest is all hand-built. I guess I'm in for a major effort for that city. Edited by user 30 January 2017 21:26:41(UTC)

| Reason: Added pic of profiles to show how customtraxx's Code83 solution dowsn't work for NEM wheelsets. |

|

2 users liked this useful post by Minok

|

|

|

|

Joined: 15/10/2006(UTC) Posts: 2,319 Location: Washington, Pacific Northwest

|

Roco finally confirmed that both their trams for 2017 (well really 2018 based on Dec 2017/Jan2018 market delivery) do 250mm bends. So tight bends it is, and that means Tillig/Luna track, or I'll be hand bending two types of track and hand-laying (the right most of the above sample profiles), since the US based 'tram track' solutions that are premade are in the middle camp - the valley is much too shallow for H0 scale wheels as the trams would ride on the flange edges rather than the wheels/traction-tires.

My hands hurt just thinking about that forming labor... |

|

|

|

|

|

|

Joined: 08/04/2007(UTC)

Posts: 25

Location: Jackson, WI

|

|

1 user liked this useful post by Turbo T Terry

|

|

|

|

Joined: 15/10/2006(UTC) Posts: 2,319 Location: Washington, Pacific Northwest

|

Originally Posted by: Turbo T Terry  Cool find. Unfortunately the 171mm radius curves are too tight as the trams can only turn 250mm curves (or at least thats the rating from Roco). |

|

|

|

|

|

|

Joined: 20/01/2015(UTC) Posts: 1,204 Location: Kerikeri

|

Havnt done this myself but have thought about it lot. I suggest you buy separated rails and preform them into the shapes you want. As this is a street car arrangement, there wont be the need to see the sleepers so that wont be a problem [ you probably wont need sleepers either, just glue the lot onto some sort of surface yo choose ]. You could then set them in the road bed like the real thing. Just dont have any joins near the curves.

Dereck

Ps a friend of mine said it can be a pain in the arse to use flex tracks on bends because of the memory of the rails. |

Northland. NZ REMEMBER 0228 for ä |

1 user liked this useful post by dominator

|

|

|

|

marklin-users.net community | Forum

»

General topics

»

H0-scale

»

250mm radius curves - flex track or fixed track pieces

Forum Jump

You cannot post new topics in this forum.

You cannot reply to topics in this forum.

You cannot delete your posts in this forum.

You cannot edit your posts in this forum.

You cannot create polls in this forum.

You cannot vote in polls in this forum.