Joined: 02/01/2006(UTC) Posts: 878 Location: Stockholm, Sweden

|

Wounderful Pierre! You are working on a detail level, to which I've never even been close.

It is very much inspiring to see the progress of your work. So much, I've ordered a kit like this to make the same conversion. I will really do my outmost to put the effort into the details this time. |

|

|

|

|

|

|

Joined: 09/11/2004(UTC)

Posts: 2,346

Location: Longueuil, Quebec

|

Hello ! I completed the pit by laying a mix of ballasts from Woodland Scenics : B72 Fine Brown B75 Fine Grey B78 Medium Brown B82 Medium Grey B1376 Fine Cinders The ballast was glued with the usual technique and Woodland Scenics "Scenic Cement" S191. Here is the result :

|

|

|

|

|

|

Joined: 09/11/2004(UTC)

Posts: 2,346

Location: Longueuil, Quebec

|

The first phase of this conversion project is now completed !  I now have to wait for the building of my layout to start the second phase which will consists in connecting the turntable with the K-Tracks, trimming the bridge's rail ends, completing the connections and closing the motor and driving wheel housing under the pit. This would probably not occur prior next autumn. To date, this project has cost me exactly CDN$ 88.97 (about Euros 60.00) including ballast but excluding paint, Humbrol and CA glues. It took me about 30 hours or work to achieve this conversion to date. Here are some further pictures with my UP PA-1 on the bridge :      The turntable motor electric power cable can be seen on the last picture. It goes from the top of the power arch to the junction box that I added under the deck as described in a previous report. Pierre.

|

|

|

|

|

|

Joined: 10/07/2002(UTC) Posts: 3,298 Location: Patagonia

|

Just great Pierre!!!!

Congratulations!!!!! |

German trains era I-II and selected III, era depends on the mood, mostly Maerklin but i can be heretic if needed XD, heresy is no longer an issue.. LOL |

|

|

|

|

|

Joined: 25/07/2001(UTC)

Posts: 11,165

|

|

Juhan - "Webmaster", at your service...

He who asks a question is a fool for five minutes. He who does not ask a question remains a fool forever. [Old Chinese Proverb] |

|

|

|

|

|

Joined: 12/05/2005(UTC)

Posts: 1,908

Location: Stockholm, Sweden

|

Well done! Very inspiring!!! |

|

|

|

|

|

|

Joined: 21/10/2004(UTC) Posts: 31,697 Location: United Kingdom

|

Congratulations,Great work. |

Large Marklinist 3- Rails Layout with CS2/MS2/Boosters/C-track/favorites Electric class E03/BR103, E18/E118, E94, Crocodiles/Steam BR01, BR03, BR05, BR23, BR44, BR50, Big Boy. |

|

|

|

|

|

Joined: 09/11/2004(UTC)

Posts: 2,346

Location: Longueuil, Quebec

|

Quote:[size=1" face="Verdana" id="quote]quote:Originally posted by Martin T

<br />Wounderful Pierre! You are working on a detail level, to which I've never even been close.

It is very much inspiring to see the progress of your work. So much, I've ordered a kit like this to make the same conversion. I will really do my outmost to put the effort into the details this time.

Thanks Martin. I have to admit that I lacked of inpiration when I decided to put ballast into the pit. I tried to find pictures of turntables on Internet and I just found one fitted with nice clean grey gravel in a museum in the USA. All the other-ones had their bottom made of mud, swamp, vegetation, ... but nothing like gravel exposed to the elements for years. So I tried that mix. I hope now that it is convincing ! I would be happy to see your own convertion, so please post pictures of your work. If you need further information, feel free to send me an e-mail. Have fun now as I had ! Pierre.

|

|

|

|

|

|

Joined: 09/11/2004(UTC)

Posts: 2,346

Location: Longueuil, Quebec

|

Thanks for your support my friends.

Pierre.

|

|

|

|

|

|

Joined: 10/02/2004(UTC)

Posts: 2,162

Location: Portugal

|

Well, congratulations on another very realistic and highly convincing piece of modelling work! indeed quite inspiring!

Luis

|

|

|

|

|

|

Joined: 08/12/2004(UTC) Posts: 4,430 Location: Attiki Athens Greece

|

Great job.Congratulations.

|

|

|

|

|

|

Joined: 17/07/2005(UTC) Posts: 260 Location: Viña del Mar, Chile

|

[:0][:0][:0][:0][:0][:0][:0][:0][:0][:0][:0]

Great job.

Are you using kadee? Don't you have troubles with turnout pukos?

|

|

|

|

|

|

Joined: 22/04/2004(UTC) Posts: 12,139 Location: New York, NY

|

Unbelievable - excellent job [:p][:p][:p] !!!

Congratulations, Pierre !!!

John

|

I hope no one visits a poor Southener's layout in Brooklyn. Intruders beware of Gators.

AT&SF, D&RGW, T&P, SP, WP, UP, BN, NYC, ARR, epI-III - analog & digital Marklin Classics only.

CU#6021 FX-MOTOROLA DIGITAL SYSTEM. Fast as lightning and no trouble. What else ...

Outlaw Member of BIG JUHAN's OUTSIDER CLUB. With the most members, worldwide

|

|

|

|

|

|

Joined: 09/11/2004(UTC)

Posts: 2,346

Location: Longueuil, Quebec

|

Thanks !

I hope to add more details about the conversion on my website soon.

Pierre.

|

|

|

|

|

|

Joined: 30/11/2004(UTC) Posts: 690 Location: Justo ahí

|

That´s a great job! Nice wathering.

|

Band on the run |

|

|

|

|

|

Joined: 13/10/2004(UTC) Posts: 2,616

|

Hi Pierre,

I looks very realistic.

Absolutely beautiful [:p]

Kind regards

Guus |

Kind regards,

Guus |

|

|

|

|

|

Joined: 02/01/2006(UTC) Posts: 878 Location: Stockholm, Sweden

|

Hello Pierre! I'm proud to announce that I now (almost) have completed the same conversion. I want to thank you again for this inspiring thread you have made in this forum about this conversion! I followed almost exactly your conversion, but with three differences; 1. I kept the bracing in the bridge structure and instead cut a slot straight through it. The slot was made with a miniature drilling machine mounted on a coordinate table. The slot was cut to the same width as the centerrail of the 5106. After mounting the two centerrails I added glue and used the bracing as support for the centerrail. 2. I had to go up in size of the rails used on the brigde deck to Roco code 100 flexitrack. Otherwise the brigde track got too low to mate with my M-rail (5000-series) Märklin tracks. 3. I didn't mount the power arch, since I will not have any power lines on my layout. I'll still have some remaining paint job in the pit, but otherwise very happy with this turntable. It's my first, so you can understand my happiness! I didn't want to attach photos of my conversion in "your canvas" here, but have published a few on my website: http://web.telia.com/~u87724996...rail/m5000/mrail_mod.htmThank you and keep up with the good railroad work all over the world! Regards / Martin in Sweden |

|

|

|

|

|

|

Joined: 09/11/2004(UTC)

Posts: 2,346

Location: Longueuil, Quebec

|

Quote:[size=1" face="Verdana" id="quote]quote: Originally posted by Martin T<br />Hello Pierre! I'm proud to announce that I now (almost) have completed the same conversion. I want to thank you again for this inspiring thread you have made in this forum about this conversion! I followed almost exactly your conversion, but with three differences; 1. I kept the bracing in the bridge structure and instead cut a slot straight through it. The slot was made with a miniature drilling machine mounted on a coordinate table. The slot was cut to the same width as the centerrail of the 5106. After mounting the two centerrails I added glue and used the bracing as support for the centerrail. 2. I had to go up in size of the rails used on the brigde deck to Roco code 100 flexitrack. Otherwise the brigde track got too low to mate with my M-rail (5000-series) Märklin tracks. 3. I didn't mount the power arch, since I will not have any power lines on my layout. I'll still have some remaining paint job in the pit, but otherwise very happy with this turntable. It's my first, so you can understand my happiness! I didn't want to attach photos of my conversion in "your canvas" here, but have published a few on my website: http://web.telia.com/~u87724996...rail/m5000/mrail_mod.htmThank you and keep up with the good railroad work all over the world! Regards / Martin in Sweden Superb job ! Congratulations. I really like your concrete weathering of the pit. Congratulations for your really nice website as well; it looks very professional. BTW, it is not "my canvas" ... Feel free to post pictures here if you wish ! What will be your next project ? From my side, I am currently working on Walthers Cornerstore Concrete Coaling Tower # 933-3042 ( http://www.walthers.com/exec/productinfo/933-3042 ). Pierre.

|

|

|

|

|

|

Joined: 06/01/2004(UTC)

Posts: 913

Location: The Central Coast

|

Pierre,wow  great work[:p] |

worse things happen at sea |

|

|

|

|

|

Joined: 12/01/2003(UTC)

Posts: 2,528

Location: Groton, Connecticut

|

Nice work both of you.

Ira |

Building German Era I-II layout(Mk IIIc).  |

|

|

|

|

|

Joined: 20/04/2003(UTC) Posts: 2,248 Location: Amsterdam, Netherlands; Göteborg, Sverige,

|

Very impressive, the work both of you did! How are you planning to operate the turntable? |

Sander

---

Era I(b): K.Bay.Sts.B. and K.W.St.E. |

|

|

|

|

|

Joined: 02/01/2006(UTC) Posts: 878 Location: Stockholm, Sweden

|

Hi! Martin here... Walthers are offering a geared motor which fit the kit. Construction looks good, so I think only need to build a voltage regulator to get the right speed on the movement. However, I haven't got the motor yet, so I have not been able to try it out.

I will manouver the turntable with a simple 3-position toggle switch. I was thinking of adding a PCB inside the turntable, which would make the stopping automatic, but I hesitate now. I think that manually operated turntable is the way to go anyway. |

|

|

|

|

|

|

Joined: 09/11/2004(UTC)

Posts: 2,346

Location: Longueuil, Quebec

|

Quote:[size=1" face="Verdana" id="quote]quote:Originally posted by Martin T

<br />Hi! Martin here... Walthers are offering a geared motor which fit the kit. Construction looks good, so I think only need to build a voltage regulator to get the right speed on the movement. However, I haven't got the motor yet, so I have not been able to try it out.

I will manouver the turntable with a simple 3-position toggle switch. I was thinking of adding a PCB inside the turntable, which would make the stopping automatic, but I hesitate now. I think that manually operated turntable is the way to go anyway.

I will do just like Martin : a DPDT three-position toggle switch to control the Walthers 12VDC motor. I will perhaps add a serie resistor with a parallel mounted by-pass SPST switch to control speed if required. Will see when installing the turntable in the layout. Thanks to all for your support. Pierre.

|

|

|

|

|

|

Joined: 09/12/2004(UTC)

Posts: 45

Location: Spain

|

Hi Pierre:

You are an artist! Both technically and, let's say, in the artist way.

Congratulations for your superb work.

Santi

|

|

|

|

|

|

Joined: 09/11/2004(UTC)

Posts: 2,346

Location: Longueuil, Quebec

|

I have added a French description of this conversion on my website for our French speaking friends : Les amis de langue française pourront trouver une description de la conversion en français sur mon site : http://www.pierregillard...n/projets/u01/index.htmlPierre. PS : Thanks for your compliment, Santi.

|

|

|

|

|

|

Joined: 02/01/2006(UTC) Posts: 878 Location: Stockholm, Sweden

|

Cleaning of contact surfaces required

It's important to clean the brass conductor rings + spring contacts blades after installation with Isopropanol, or Aceton. Otherwise contact is poor and gives intermittent voltage drops when turning the table.

Anti-rotation properties w/o installed motor

The table is very easy to turn before the motor is installed. So easy, it gets out of position when the loco enter and exit. How are these properties with motor installed Pierre? |

|

|

|

|

|

|

Joined: 21/10/2004(UTC) Posts: 31,697 Location: United Kingdom

|

Excellent link.  |

Large Marklinist 3- Rails Layout with CS2/MS2/Boosters/C-track/favorites Electric class E03/BR103, E18/E118, E94, Crocodiles/Steam BR01, BR03, BR05, BR23, BR44, BR50, Big Boy. |

|

|

|

|

|

Joined: 09/11/2004(UTC)

Posts: 2,346

Location: Longueuil, Quebec

|

Quote:[size=1" face="Verdana" id="quote]quote:Originally posted by Martin T

<br />Cleaning of contact surfaces required

It's important to clean the brass conductor rings + spring contacts blades after installation with Isopropanol, or Aceton. Otherwise contact is poor and gives intermittent voltage drops when turning the table.

Anti-rotation properties w/o installed motor

The table is very easy to turn before the motor is installed. So easy, it gets out of position when the loco enter and exit. How are these properties with motor installed Pierre?

Unfortunately, I am not so far advanced. Adding motor and drive mechanism will take place only when I will build my layout module ... let's say next October to the best. But I think that with the important demultiplication between the large bridge drive gear and the small motor gear, there will be no problem. Thanks for the contact advise. It is my time now to be inspired by your work, Martin ! Another option for the contact was proposed earlier in this topic by Jonquinn. Pierre.

|

|

|

|

|

|

Joined: 09/04/2006(UTC)

Posts: 1,278

Location: Brisbane, Queensland

|

Giday.The builders of the turntables might find an article in this months * RAILROAD MODEL CRAFTSMAN ,April 2006 of some interest. Scratchbuilding a quarry turntable,by Trevor Marshall There is a sub article by Chris Abbot, Creating a turntable mechanism. This is a really great magazine and it might have some ideas that the turntable modeller might find of interest. Of course on the other hand Martin T and Pierre GILLARD might want to post a link to the Märklin Users site ..... "this is how ya build a turntable mate!!!!!!!!" * The canoe and horse drawn Zepplin make for slow delievery.

|

|

|

|

|

|

Joined: 09/11/2004(UTC)

Posts: 2,346

Location: Longueuil, Quebec

|

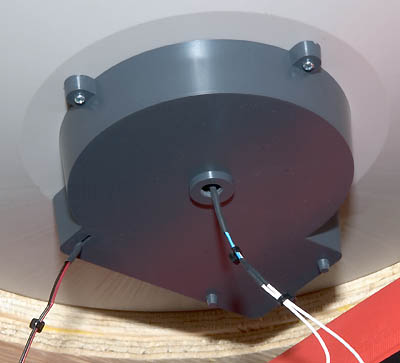

Again on my turntable ... I have read several reports about the reliability of the Walthers turntable brass rings and wipers contact system. So I decided to keep the system as simple as possible ... even that it cannot be simpler ! As a matter of fact, I drilled a small hole at the extremity of the bridge axle in order to let both rail power wires going through it. I soldered two 40-50 cm multibraid AWG 22 wires at their end. The idea is then that the wires will simply twist when the bridge will turn. Statistically, the number of clockwise revolutions should equal the number of counterclockwise revolutions. Anyway, if the two wires should be once to much twisted, it just requires to disconnect both wires under the table, untwist and reconnect them.  At the same time, I have installed Walthers # 933-1050 motor in the gear housing. Both wires are maintained by masking tape. I also added a protecting sleeve around the wires at the housing slot level. A hole has been drilled in order to allow rail power wires going outside.  Pierre.

|

|

|

|

|

|

Joined: 16/08/2006(UTC) Posts: 5,382 Location: Akershus, Norway

|

Pierre and Martin,

I certainly envy you people with such a patient and skills in this detailed work. Really nice! |

Best regards Svein, Norway

grumpy old sod

|

|

|

|

|

|

Joined: 09/11/2004(UTC)

Posts: 2,346

Location: Longueuil, Quebec

|

Thanks Svein !  The turntable is almost completed now ! The geared wheel was glued on the bridge axle. Even if not used as contact, I have however glued both brass tubes on the axle as well :  Then the gear housing was screwed :  A remote control was assembled with : 1. A LED to check presence of 12 VDC power for the turntable motor. 2. A "CW"/"CCW" intermittent switch (DPDT, ON-OFF-ON). 3. A "HI/LO" turntable speed switch.  A test is then conducted with my NYC Alco PA-1 ... and it is a SUCCESS ! :   Nevertheless, with a 12 VDC power supply, the motor turns too fast for a precise adjustment of the bridge. So, I reduced the voltage and found that it could be fine with 6 VDC. In order to get the two turntable speeds, I will now add a 120 ohm/1 W serial resistor inside the remote that will be by-passed by the "HI/LO" switch in "HI" position (current is about 50 mA under 6 VDC). So I am really happy and pleased with this conversion as I progressively reach the final steps.  Pierre.

|

|

|

|

|

|

Forum Jump

You cannot post new topics in this forum.

You cannot reply to topics in this forum.

You cannot delete your posts in this forum.

You cannot edit your posts in this forum.

You cannot create polls in this forum.

You cannot vote in polls in this forum.